Operation mode:380V Three-Phase

Application area:Non-woven fabric industry-conveying machinery、Aluminum profile processing-compound machine、Stone machinery-bridge、 cutting machine、Plastic Machinery—Plastic Pipe Conveyor、Plastic equipment-blister mac

PR6100 series inverter is of sensor-less vector control frequency inverter with high torque, high accuracy and wide range of speed regulation, designed with the brand-new idea. Based on improving stability, it is provided with many run and control functions such as motor parameters auto-tune, simple PLC control, practical PID adjustment, flexible input/output terminal control, parameter online amendment, pulse frequency setting, power-off and stopping parameter storage, wobbling control , RS485 communication, constant pressure water supply control and so on. This inverter provides equipment manufacturer and terminal user with integrated solution of high integration level; helps to reduce the system purchase and operation cost, and improves the reliability of system.

1. Advanced vector control algorithm, can realize the decoupling control of motors, and reach SVC current vector control mode and V/F control mode;

2. 150% low frequency moment output, 1:100 speed controlrange, control accuracy of the non PG vector controlspeed can reach to 0.1%;

3. Frequency inverters between 0.75kw~18.5kw with built-in brake unit, if fast-action braking is needed, can connect brake resistance directly; 160kw and up with direct current (DC) reactor, which can increase the power factor of the output side, increase efficiency and stability of the AC Driver, eliminate the influence of higher harmonics produced at the input side toward the frequency inverter, decrease the interference to periphery;

4. Built-in auto-compensation torque function, built-in PID regulator and built-in RS485 communication interface, provide full support to MODBUS communication protocol;

5. Restart function of torque tracking, realize smooth andnon-impact start of the revolving motor;Multi-paraemeter monitoring and adjustment online;

6. Connected with various ancillary equipment, such as PLC, IPC and meters by various input and output ports and control modes;

7. LED, LCD operation panel optional for convenience and efficiency; Supply pulse input and output to achieve digital closed loop control method;

8. With automatic energy saving feature, at which the current is lower than V/F at the same frequency; the voltage automatic adjustment to keep the output voltage constant when the power voltage change; Complete independent air flue design increase vigilance against dust atmosphere;

9. All boards processed by conformal coating;

10. Perfect function of protection;

Non-woven fabric industry-conveying machinery、Aluminum profile processing-compound machine、Stone machinery-bridge、 cutting machine、Plastic Machinery—Plastic Pipe Conveyor、Plastic equipment-blister machine、Engraving machine、Printing equipment-flat screen printer、Coil production line—winding machine;

Product List

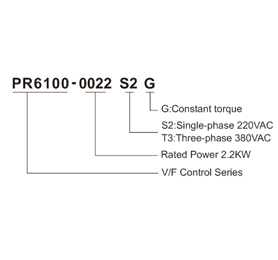

| Voltage class | Model | Rated output Current (A) | Applicable motor (KW) |

| 220V Single-phase | PR6100-0004S2G | 2.5 | 0.4 |

| PR6100-0007S2G | 4 | 0.75 | |

| PR6100-0015S2G | 7 | 1.5 | |

| PR6100-0022S2G | 10 | 2.2 | |

| 380V Three-phase | PR6100-0007T3G | 2.3 | 0.75 |

| PR6100-0015T3G | 3.7 | 1.5 | |

| PR6100-0022T3G | 5 | 2.2 | |

| PR6100-0040T3G | 8.5 | 4 | |

| PR6100-0055T3G | 13 | 5.5 | |

| PR6100-0075T3G | 17 | 7.5 | |

| PR6100-0110T3G | 25 | 11 | |

| PR6100-0150T3G | 33 | 15 | |

| PR6100-0185T3G | 39 | 18.5 | |

| PR6100-0220T3G | 45 | 22 | |

| PR6100-0300T3G | 60 | 30 | |

| PR6100-0370T3G | 75 | 37 | |

| PR6100-0450T3G | 90 | 45 | |

| PR6100-0550T3G | 110 | 55 | |

| PR6100-0750T3G | 150 | 75 | |

| PR6100-0930T3G | 176 | 90 | |

| PR6100-1100T3G | 210 | 110 | |

| PR6100-1320T3G | 250 | 132 | |

| PR6100-1600T3G | 310 | 160 | |

| PR6100-2000T3G | 380 | 200 | |

| PR6100-2200T3G | 415 | 220 | |

| PR6100-2450T3G | 475 | 245 | |

| PR6100-2800T3G | 510 | 280 | |

| PR6100-3150T3G | 605 | 315 | |

| PR6100-3500T3G | 800 | 350 | |

| PR6100-4000T3G | 900 | 400 | |

| PR6100-5000T3G | 1000 | 500 | |

| PR6100-5600T3G | 1200 | 560 | |

| PR6100-6300T3G | 1300 | 630 |

Performance Indexes

| Item | Specifications | |

| Input | Rated voltage and frequency | Single-phase 220V ; Three-phase 220V ; Three-phase 380V; 50Hz / 60Hz |

| Variable allowable value | Voltage: -20% ~ 20%; Voltage unbalance: <3% ; Frequency:±5% | |

| Output | Rated voltage | 0~200V /0~380V |

| Frequency range | 0Hz~400Hz | |

| Overload capability | 150% for 1 min, 180% for 1s, 200% instant protection | |

| Main control function | Modulation mode | Space voltage vector PWM control ; |

| Control mode | Sensorless vector control (SVC) | |

| Frequency accuracy | Digital setting: Max frequency ×±0. 01%; Analog setting: Max frequency ×±0. 2% | |

| Frequency resolution | Digital setting: 0.01Hz ; Analog setting: Max frequency ×0.1% | |

| Starting Frequency | 0.0Hz~10.00 Hz | |

| Torque rise | Auto torque rise, manual torque rise 1%~30.0%(valid for V/F) | |

| V/F curve | Three ways:Linear V/F curve, square V/F curve, user self-defining V/F curve | |

Acceleration/deceleration curve | Optional time unit (Min/s), the longest: 3600s (settable in the range of 0.1~3600s). | |

| DC braking | Be optional during both starting and stopping, the operating frequency: 0~20Hz, operating time: settable within 0~30s | |

| Jogging | Jogging frequency range: 0.1~50.00Hz,jogging acceleration and deceleration time: 0.1~3600s. | |

| Built-in PID | It is convenient for forming closed loop control system,applicable for course control like pressure and flow, etc. | |

| Multi-speed operating | Realize multi-speed running by built-in PLC or control terminal. | |

Weaving wobble frequency | Can get wobble frequency of adjustable central frequency | |

| Auto voltage adjustment | When main voltage changes,the output voltage may be kept constant by adjusting PWM output (AVR function). | |

| Auto energy-saving running | According to load condition,V/F curve can be optimized automatically to get the aim of energy-saving running. | |

| Auto current limiting | Limit in-service current automatically, so as to avoid tripping for fault caused by frequent over current. | |

| Sensorless vector control | Torsion characteristic | 150% output of torque at 1Hz, rev accuracy: 0.1% |

| Motor parameters automatic read | Reading the parameters from motor when completely stop in order to achieve optimal controlling effect. | |

| Running function | Running command passage | Setting of operating manual; setting of control terminal; setting of serial port; switching by three ways. |

Frequency setting passage | Setting of keyboard analog potentiometer; setting of keyboard ,▲,▼ keys; | |

| setting of functional code digits; setting of serial port, setting of terminal UP/DOWN, | ||

| setting of analog voltage, setting of analog current ; setting of impulse, setting of combination; | ||

| switching at any time by kinds of setting ways. | ||

| Switch input passage | Forward/reverse rotating command, 6-way programmable switching value input to set 30 functions. | |

| Analog input passage | 2-way analog signal input, 0~20mA, 0~10V optional. | |

| Analog output passage | Analog signal output 0~10V,0~20mA to get output of physical quantity,like frequency and output frequency。 | |

| Switch output passage | 3-way programmable open collector output; 1-way relay output signal; can output different physical quantities. | |

| Operating panel | LED display | Display setting frequency, output voltage, and output current and so on. |

Display external instrument | Display output frequency, output current, and output voltage and so on. | |

| Protection function | Over current protection, over voltage protection, under voltage protection,over heat protection, over load protection. | |

| Option | Braking unit, remote operating panel, remote cable, soleplate of keyboard. | |

| Environment | Service location | Indoors, not suffer from sun, dust, corrosive gas, oil fog, and steam and so on. |

| Altitude | Shorter than 1000m (derating at higher than 1000m) | |

Environment temperature | -10°C ~ +40°C | |

| Humidity | Less than 90%RH, no condensation | |

| Vibration | Less than 5.9m/s²(0.6M) | |

| Storage temperature | -20°C ~ +60°C | |

| Structure | Protection class | IP20 (In service state or keyboard state.) |

| Cooling way | Air-blast cooling | |

| Installation Way | Wall-hanging, Cabinet | |